In today’s design-driven world, off-the-shelf solutions are no longer enough—especially when it comes to architectural and interior elements like decorative mesh. As architects, designers, and fabricators push the boundaries of form and function, the demand for custom decorative mesh solutions has grown significantly. From unique patterns and finishes to custom sizing and materials, customization plays a vital role in ensuring that decorative mesh meets both aesthetic and technical project requirements. But how does this impact the supply chain—and why should it matter to buyers? Let’s take a closer look at the role of customization in the decorative mesh supply chain and how it adds value at every stage.

Why Customization Matters in Decorative Mesh

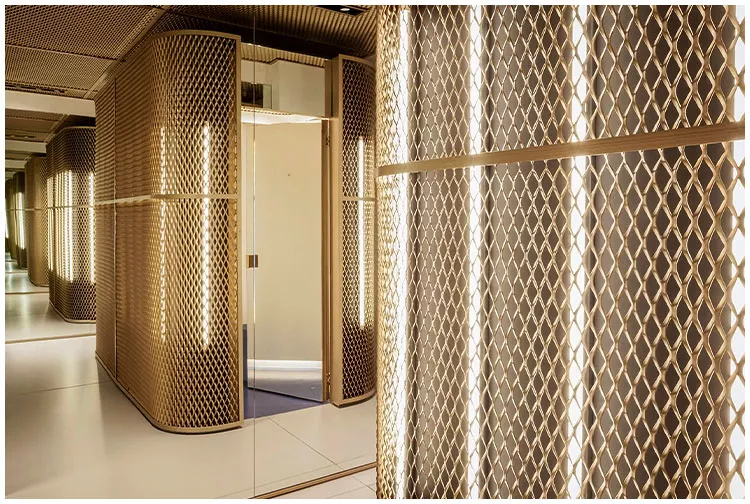

Decorative mesh is used in a wide range of applications, including:

-

Architectural facades

-

Interior partitions and walls

-

Furniture and cabinetry

-

Lighting design

-

Balustrades and railing infills

-

Signage and branding features

Each of these applications may have unique requirements for pattern, openness, finish, strength, fire rating, or material type. This makes customization essential—not a luxury.

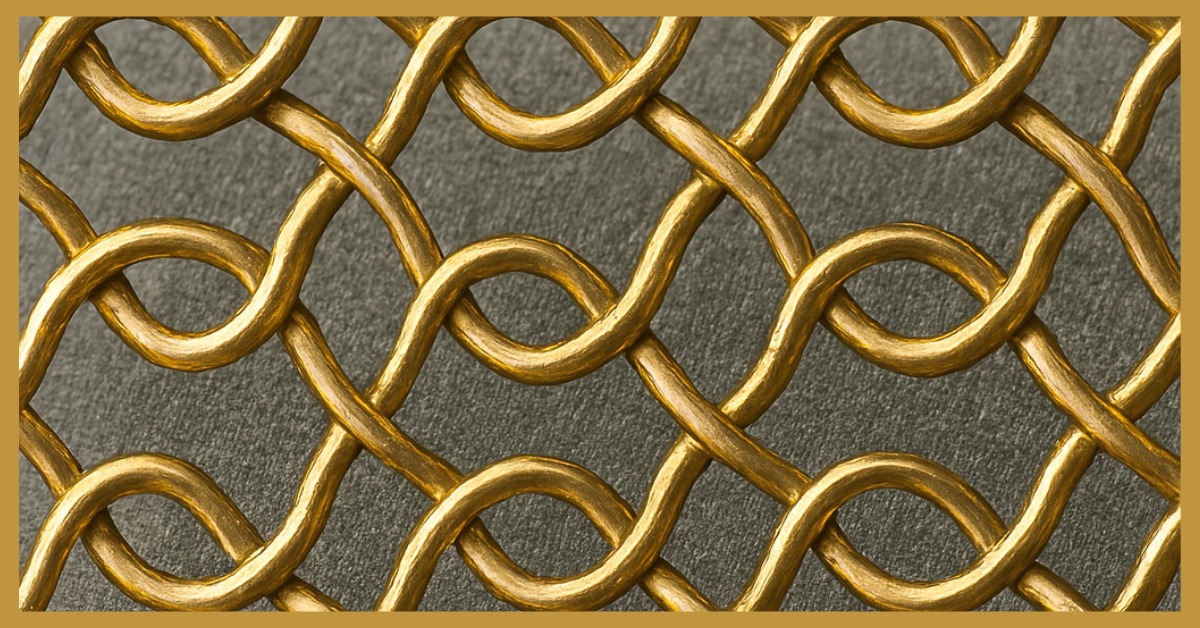

1. Design Flexibility and Creative Freedom

Customization gives architects and designers the freedom to turn concepts into reality. Whether it’s a bespoke pattern that reflects a brand identity or a non-standard mesh size for a complex space, custom mesh allows for true design expression.

Example: A hospitality designer may request a laser-cut aluminum mesh with a geometric pattern that complements the hotel’s overall design language—something a standard mesh product cannot offer.

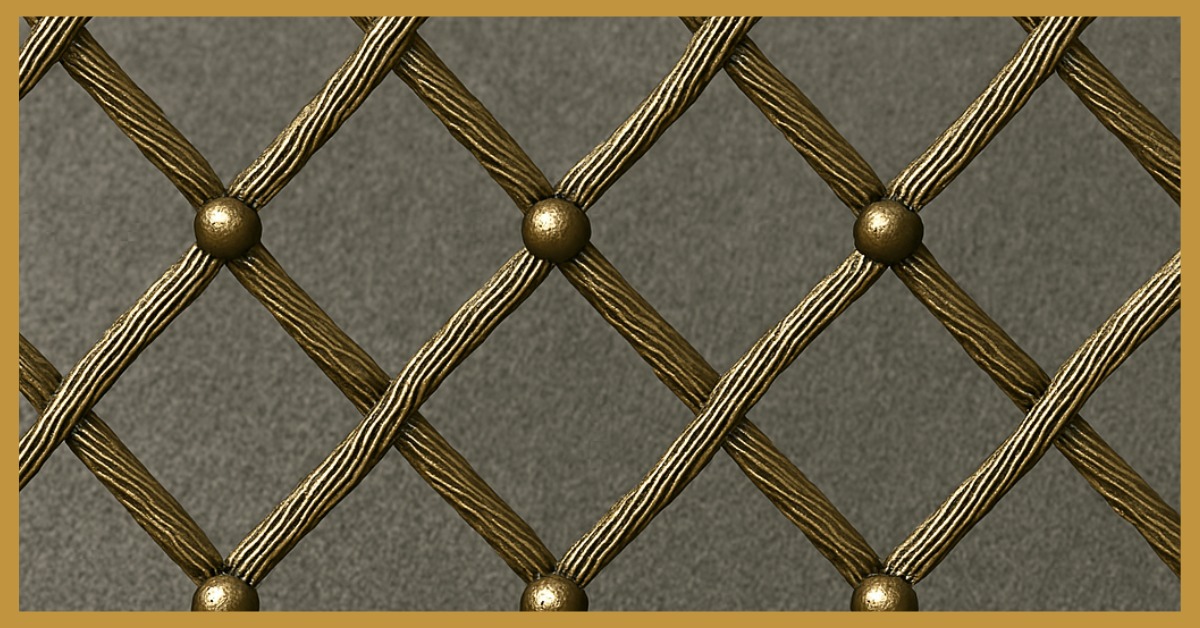

2. Material and Finish Selection

Different environments demand different materials. For instance:

-

Stainless steel is preferred for corrosion resistance in outdoor applications.

-

Brass or copper may be chosen for warm, luxury interiors.

-

Powder-coated finishes can be matched to custom color schemes.

Customization ensures the mesh not only looks right but also performs under specific environmental conditions.

3. Sizing and Installation Efficiency

Pre-cut, custom-sized mesh panels reduce waste, save time on-site, and improve installation accuracy. Suppliers that offer made-to-measure solutions help streamline the construction or fit-out process, making life easier for installers and contractors.

Benefit: Fewer onsite adjustments mean reduced labor costs and fewer delays.

4. Meeting Technical & Regulatory Requirements

In many commercial or public spaces, mesh panels must comply with fire safety, load-bearing, or ventilation requirements. Customization allows engineers and fabricators to tweak materials, mesh aperture, and reinforcement details to meet codes without compromising on design.

5. Strengthening Supplier-Client Collaboration

When customization is part of the supply chain, suppliers become strategic partners, not just product providers. They work closely with clients to:

-

Develop prototypes or samples

-

Offer technical guidance

-

Ensure feasibility and manufacturability

-

Suggest alternative materials or designs when needed

This collaborative approach leads to better outcomes and long-term relationships.

How Suppliers Handle Custom Decorative Mesh Orders

Reliable decorative mesh suppliers typically follow a clear customization workflow:

-

Consultation – Understanding project needs, applications, and constraints.

-

Design Proposal – Offering mesh options, patterns, finishes, and material suggestions.

-

Sampling – Providing physical or digital samples for approval.

-

Production – Manufacturing to exact specifications with quality control at every stage.

-

Delivery & Support – Timely shipping and post-sale technical support.

Challenges to Consider

While customization offers many benefits, it also adds complexity:

-

Longer lead times for production and approval

-

Higher costs than off-the-shelf products

-

Minimum order quantities in some cases

That’s why it’s important to plan early and partner with a responsive, experienced supplier who can guide you through the process.

Final Thoughts

As decorative mesh becomes a focal point in architecture and design, customization is no longer optional—it’s essential. It allows designers to bring their creative visions to life, ensures compliance with technical requirements, and adds precision to the installation process.

At the heart of it all is a supply chain that’s agile, collaborative, and built around the unique needs of every project.