Industrial filtration is undergoing a rapid transformation as industries demand higher efficiency, durability, and precision. Traditional filtration materials are struggling to meet modern operational challenges such as extreme temperatures, corrosive environments, and the need for consistent performance. This is where smart woven wire mesh is emerging as a game-changing solution.

With its advanced design, adaptability, and long service life, smart woven wire mesh is quickly becoming the preferred choice for industrial filtration systems across sectors like oil & gas, pharmaceuticals, food processing, chemicals, and water treatment.

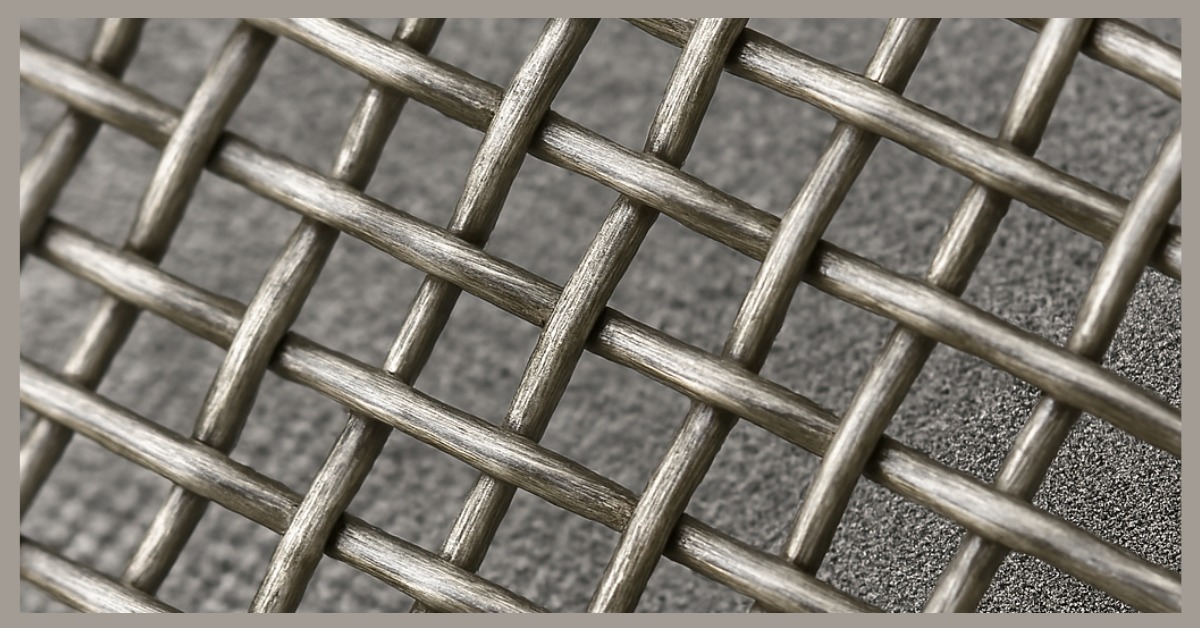

Understanding Smart Woven Wire Mesh

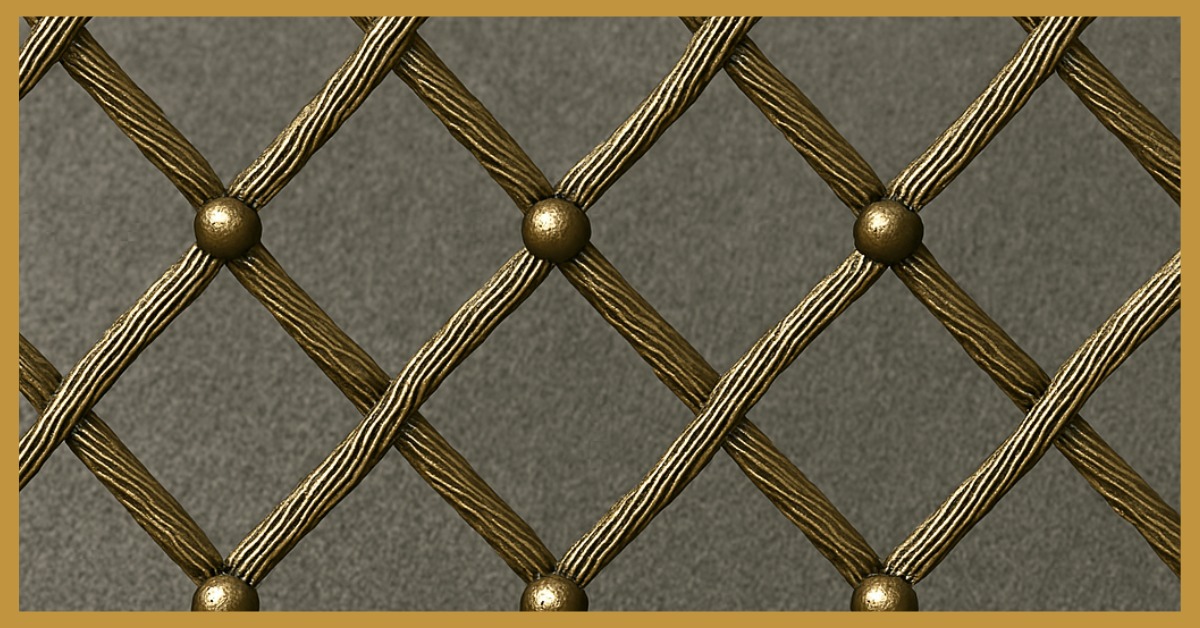

Smart woven wire mesh is an engineered filtration material made by weaving high-quality metal wires—such as stainless steel, nickel alloys, or brass—into precise, uniform patterns. Unlike conventional wire mesh, smart woven wire mesh is designed using advanced manufacturing techniques that allow greater control over pore size, wire diameter, and mesh geometry.

What makes it “smart” is its ability to deliver optimized filtration performance while adapting to demanding industrial conditions. This includes improved flow rates, higher particle retention accuracy, and enhanced mechanical strength.

The Growing Demand for Advanced Industrial Filtration

Industries today are under pressure to:

-

Improve product quality

-

Reduce downtime and maintenance costs

-

Meet stricter environmental and safety regulations

Conventional filtration media such as synthetic fabrics or perforated sheets often fail under high pressure or temperature fluctuations. Industrial filtration wire mesh, especially smart woven variants, addresses these limitations by offering superior structural integrity and long-term reliability.

Key Advantages of Smart Woven Wire Mesh in Filtration

1. Precision Filtration Efficiency

One of the biggest advantages of smart woven wire mesh is its highly accurate filtration capability. Uniform pore sizes ensure consistent particle separation, making it ideal for applications requiring micro-level filtration.

This precision helps industries maintain product purity, reduce contamination, and improve overall process efficiency.

2. Exceptional Strength and Durability

Smart woven wire mesh offers excellent resistance to:

-

High pressure

-

Abrasion

-

Extreme temperatures

-

Corrosive chemicals

This durability makes it a preferred solution for heavy-duty industrial filtration applications, where frequent replacement of traditional filters can be costly and disruptive.

3. Enhanced Flow Rates and Reduced Pressure Drop

Thanks to its open area design, woven wire mesh allows higher flow rates while maintaining filtration accuracy. This results in a lower pressure drop, which translates to reduced energy consumption and improved system performance.

Industries looking to optimize operational efficiency are increasingly turning to metal woven wire mesh filters for this reason.

4. Reusability and Easy Maintenance

Unlike disposable filters, smart woven wire mesh can be:

-

Cleaned

-

Reused

-

Reinstalled multiple times

This not only reduces waste but also lowers long-term operating costs. In industries such as food processing and pharmaceuticals, where hygiene is critical, wire mesh filters can be cleaned without degrading performance.

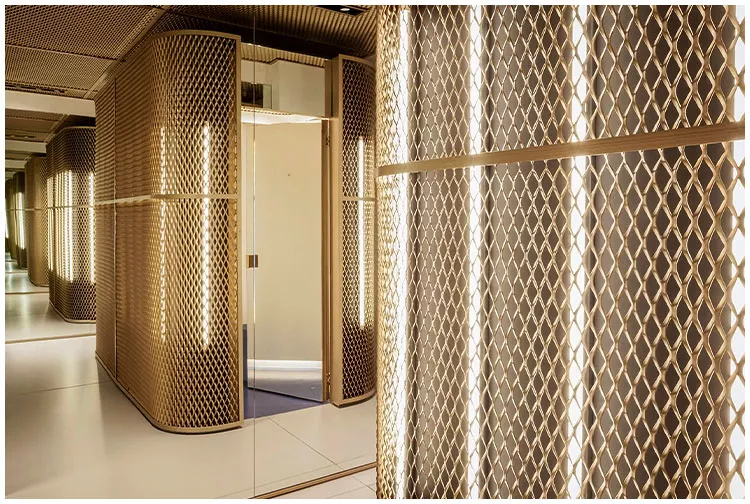

5. Customization for Diverse Industrial Applications

Smart woven wire mesh can be customized based on:

-

Mesh count

-

Wire thickness

-

Material type

-

Weave pattern

This flexibility makes it suitable for a wide range of industrial filtration solutions, from fine particle separation to coarse filtration in mining or wastewater treatment.

Applications Driving Market Growth

The rising adoption of smart woven wire mesh is fueled by its versatility across industries:

Oil and Gas Industry

Used in drilling fluids, refining processes, and pipeline filtration, woven wire mesh filters withstand extreme pressure and corrosive substances.

Chemical and Pharmaceutical Industries

Precision filtration and contamination control make smart woven wire mesh ideal for sensitive chemical processing and pharmaceutical manufacturing.

Food and Beverage Processing

Food-grade stainless steel woven wire mesh ensures hygiene, easy cleaning, and compliance with safety standards.

Water and Wastewater Treatment

Durable and corrosion-resistant wire mesh filtration systems help remove impurities while supporting long-term use.

Sustainability and Environmental Benefits

Sustainability is a major driver in modern industrial decision-making. Smart woven wire mesh contributes to eco-friendly operations by:

-

Reducing filter waste

-

Lowering energy usage due to efficient flow

-

Extending product life cycles

As industries move toward greener manufacturing practices, reusable metal filtration mesh offers a responsible alternative to disposable filtration media.

How Smart Woven Wire Mesh Supports Industry 4.0

With the rise of Industry 4.0, manufacturers are focusing on smart systems that improve monitoring and efficiency. Smart woven wire mesh integrates seamlessly into automated filtration systems by offering predictable, stable performance that supports sensor-based monitoring and data-driven maintenance strategies.

Future Outlook of Smart Woven Wire Mesh in Industrial Filtration

The global demand for advanced filtration solutions is expected to grow steadily. Smart woven wire mesh is well-positioned to lead this evolution due to:

-

Continuous innovation in mesh design

-

Development of high-performance alloys

-

Increasing need for reliable, long-lasting filtration materials

As industries continue to modernize, smart woven wire mesh will play a critical role in ensuring cleaner processes, higher efficiency, and reduced operational costs.

Conclusion

Smart woven wire mesh is no longer just an alternative—it is fast becoming the industry standard for high-performance industrial filtration. Its unmatched combination of precision, durability, reusability, and efficiency makes it the next big thing in filtration technology.

For industries seeking reliable, cost-effective, and future-ready filtration solutions, investing in smart woven wire mesh is a strategic move that delivers long-term value and operational excellence.