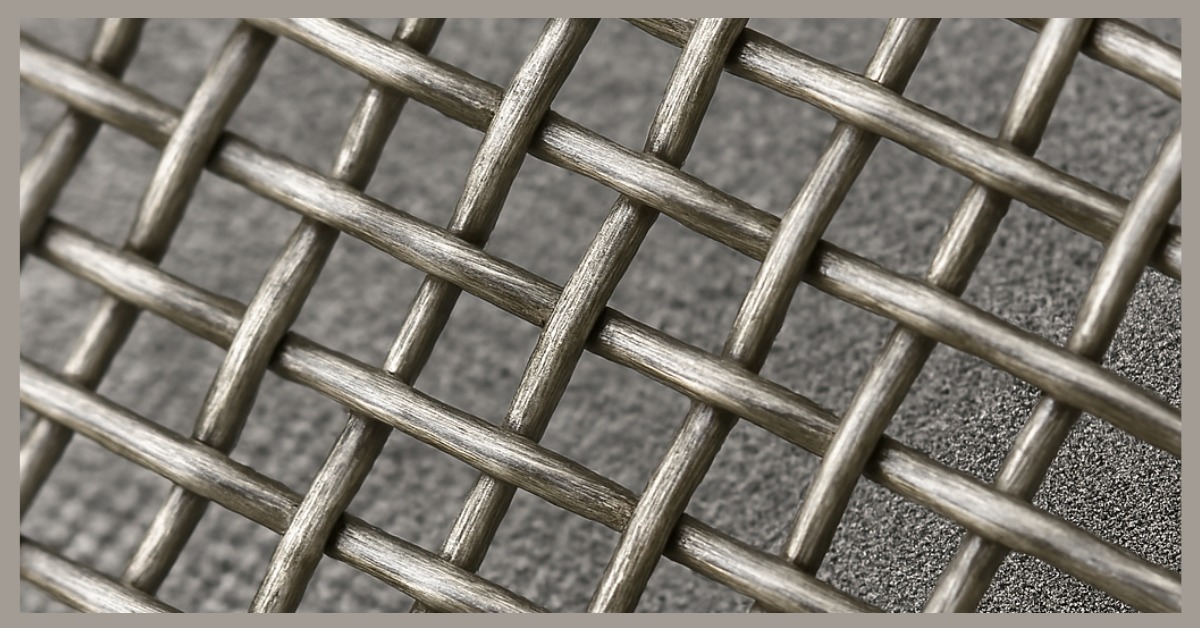

Woven wire mesh is one of the most versatile materials used across countless industries today. Known for its strength, durability, and precision, it plays a crucial role in processes that demand filtration, separation, safety, and structural support. Whether made from stainless steel, brass, or galvanized steel, woven wire mesh offers reliability and performance in even the harshest environments. In this article, we’ll explore the top 10 industrial applications of woven wire mesh and why it’s an essential material in modern manufacturing and engineering.

1. Filtration and Separation

One of the most common uses of woven wire mesh is in industrial filtration systems. It’s used to separate solids from liquids or gases in industries such as oil & gas, chemical processing, and wastewater treatment.

Why it works: The precise aperture sizes and uniform weave pattern ensure consistent filtration performance and long service life.

2. Mining and Quarrying

Woven wire mesh screens are widely used in crushing, screening, and grading equipment for mining operations. They help classify materials like sand, gravel, coal, and minerals.

Key benefits: High tensile strength, resistance to abrasion, and easy maintenance make it ideal for heavy-duty applications.

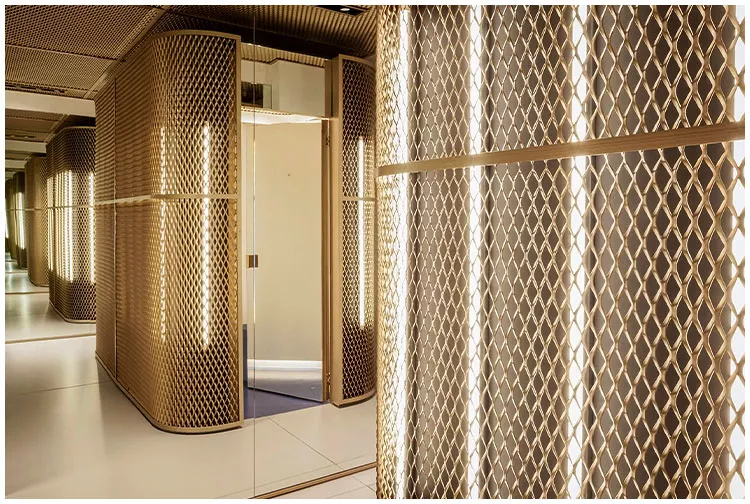

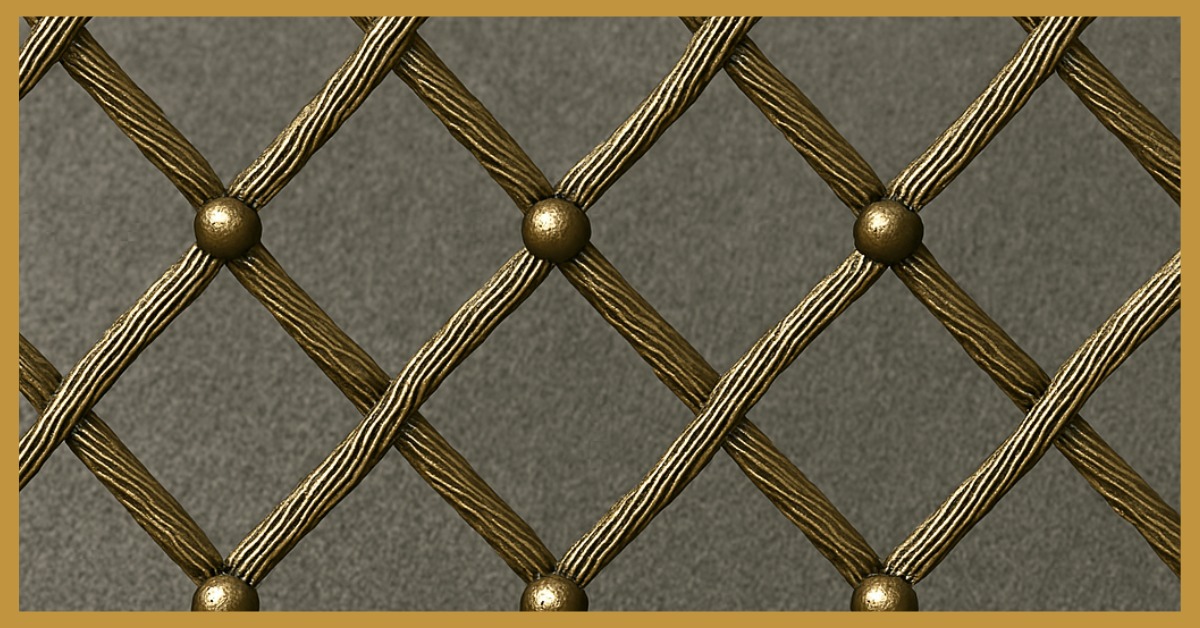

3. Construction and Architecture

Architects and builders are increasingly using decorative woven wire mesh for facades, ceilings, partitions, and railings.

Advantages: It combines aesthetics with functionality — providing ventilation, light diffusion, and safety while adding a modern design element.

4. Food and Beverage Processing

In the food industry, woven wire mesh is used for sifting, filtering, and drying applications. Stainless steel mesh ensures hygiene and compliance with food-grade standards.

Applications include: Flour sifting, sugar refining, and liquid filtration.

5. Automotive Industry

Woven wire mesh plays a key role in vehicle filtration systems, including air filters, oil filters, and exhaust components.

Benefit: It withstands high temperatures and pressures, ensuring consistent engine performance and emission control.

6. Chemical and Petrochemical Plants

In chemical plants, wire mesh is used for catalyst support, fluid bed retention, and vapor filtration.

Why it matters: Its resistance to corrosion and high temperatures ensures safety and reliability in aggressive chemical environments.

7. Aerospace and Defense

Precision woven wire mesh is critical for aerospace filtration, shielding, and reinforcement applications.

Key features: Lightweight, high strength-to-weight ratio, and reliability under extreme conditions.

8. Agriculture and Animal Protection

Farmers use woven wire mesh for fencing, crop protection, and animal enclosures.

Advantages: It offers excellent ventilation, durability, and resistance to weather — protecting both livestock and crops effectively.

9. Electronics and Energy

In the electronics and energy industries, wire mesh serves as electromagnetic shielding, battery components, and fuel cell support structures.

Why it’s important: The mesh provides conductivity, precision, and long-term stability.

10. Safety and Security

From machine guards and window screens to security fencing, woven wire mesh enhances workplace and property safety.

Benefit: Its robust structure prevents unauthorized access and ensures compliance with safety standards.

Conclusion

Woven wire mesh is more than just a material — it’s a critical engineering component used across industries to improve efficiency, safety, and performance. As technology advances, its applications continue to expand into new fields, from renewable energy to advanced filtration.

If you’re looking for high-quality woven wire mesh tailored to your industrial needs, [Your Company Name] offers a full range of materials, sizes, and custom solutions.

👉 Contact us today to discuss your project requirements or request a free quote.